Views: 0 Author: Site Editor Publish Time: 2025-09-29 Origin: Site

When planning a new kitchen or upgrading existing cabinets, the choice of hardware directly affects both function and aesthetics. Selecting the wrong Kitchen Cabinet Soft Closing Hinge often leads to issues such as misaligned doors, limited opening space, or poor closing action. To help buyers, remodelers, and procurement teams avoid these problems, this guide offers a practical step-by-step checklist that covers cabinet type, hinge size, materials, adjustment features, and fit. With the manufacturing strength of Guangdong OULA Hardware Technology Co., Ltd., you can ensure that every hinge performs reliably and adds long-term value.

Understanding the structure of your cabinet is the foundation for choosing the right hinge. Different cabinet constructions require different hinge mounting positions and angles, which means one hinge design will not fit all.

Frameless cabinets rely on hinges mounted directly to the cabinet side panel. They usually pair with full overlay doors that completely cover the box edge.

Face-frame cabinets include a front frame surrounding the box opening. Hinges must account for the frame’s thickness and can be designed for partial or full overlays.

Inset cabinets have doors set inside the frame for a flush look, which demands specialized inset hinges that provide precise alignment and clean aesthetics.

Once the cabinet style is identified, the next decision is hinge opening angle. The choice determines how wide the door can swing, which directly impacts usability in tight or spacious kitchens.

110° hinges are the standard choice, suitable for most kitchen layouts where doors open comfortably without striking nearby walls or appliances.

170° hinges provide near full access to the cabinet interior, ideal for wide pull-out drawers or large serving platters.

180° hinges are less common but useful for specialty cabinets requiring completely unobstructed openings.

Overlay describes how much the door overlaps the cabinet frame. Full overlay requires hinges that project the door outward, while partial overlay and inset designs need different mounting mechanics. Choosing incorrectly will result in poor alignment or uneven gaps.

The technical specifications of a hinge make the difference between a seamless installation and costly rework. Before ordering, measuring is essential.

Door thickness: Most soft closing hinges accommodate doors 15–22 mm thick, but thicker doors may require reinforced hardware.

Overlay: Measure how much the door covers the frame edge to determine overlay type.

Cup diameter: The hinge cup is the circular recess drilled into the back of the door. Standard cups are 35 mm, but always confirm before drilling.

Screw centers: Spacing between mounting screws ensures compatibility with pre-drilled doors or templates.

When placing a bulk order, ensure that the following are listed clearly:

Door thickness range

Overlay type and measurement

Hinge cup diameter and depth

Mounting plate height

Desired opening angle

Providing these details helps manufacturers like Guangdong OULA Hardware Technology Co., Ltd. deliver hinges that fit perfectly on arrival.

Not all hinges are created equal, especially in environments like kitchens where humidity and frequent use test durability. Choosing the correct material and finish ensures long service life and prevents costly replacements.

Steel hinges offer maximum strength and are often plated with nickel or chrome for rust resistance. They are the best choice for heavy solid wood doors.

Zinc alloy hinges provide lighter weight and stable corrosion resistance, making them suitable for medium-load applications such as laminate or MDF cabinet doors.

In humid environments, inferior finishes may show corrosion in a matter of months. High-quality hinges like those produced by OULA are tested with a 24-hour salt spray process to ensure that finish and function remain intact over years of use.

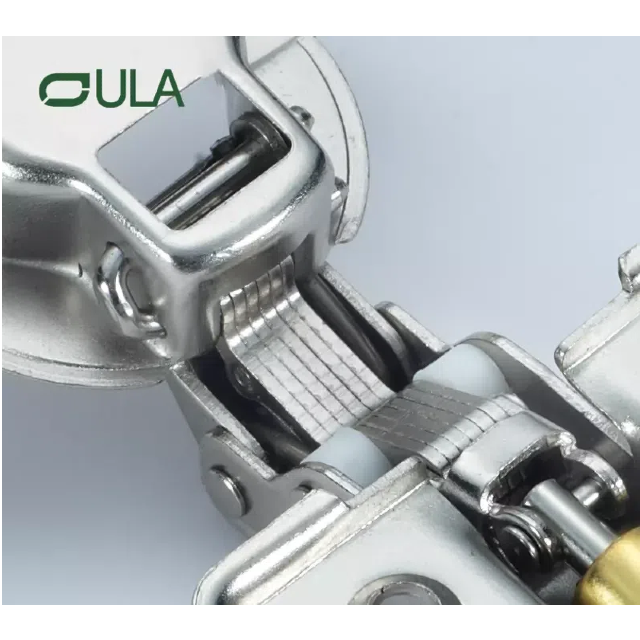

The soft-close system is the heart of the hinge. Low-quality products may fail after a short time, leaving doors to slam shut. Reliable hinges, however, integrate hydraulic or spring-dampened systems that maintain smooth performance. At OULA, every Kitchen Cabinet Soft Closing Hinge is cycle-tested up to 70,000 times to replicate years of daily opening and closing. This means your cabinets maintain their quiet, gentle close without losing strength or precision.

Even with accurate measurements, minor installation adjustments are always required. Modern hinges provide 3-way adjustability to fine-tune alignment.

Height adjustment: Moves the door up or down to align with neighboring doors. This is especially useful in kitchens with long rows of cabinetry.

Depth adjustment: Pulls the door closer to or further from the cabinet body, ensuring it closes flush without gaps.

Lateral adjustment: Shifts the door side to side, correcting uneven spacing and preventing rubbing.

These features save installers time and help create a precise, professional finish.

Soft-close hinges also benefit from tension adjustment. Being able to regulate the speed and resistance of the closing action ensures consistent results, even if doors differ slightly in weight. Without this flexibility, doors may slam shut or fail to close completely. High-quality hinges include adjustable damping systems that compensate for installation variances and long-term wear. This feature is especially valuable for large kitchens or commercial installations where uniformity matters.

To simplify procurement, a structured shopping guide ensures buyers don’t miss critical details.

When contacting suppliers, request clear confirmation on:

Opening angle (110°, 170°, or 180°)

Overlay type (full, partial, or inset)

Hinge cup diameter and depth

Door thickness compatibility

Soft-close mechanism type (hydraulic or spring-dampened)

Corrosion resistance test results

Warranty terms

Item | Quantity | Door Thickness | Overlay | Hinge Angle | Cup Size | Finish | Soft-Close Type | Notes |

Hinge | 20 pcs | 18 mm | Full | 110° | 35 mm | Nickel | Hydraulic | Face-frame cabinets |

This type of document helps ensure accuracy and avoids delays in large-scale projects. For contractors, remodelers, and kitchen suppliers, a consistent spec sheet also builds stronger communication with manufacturers.

Choosing the right Kitchen Cabinet Soft Closing Hinge requires careful consideration of cabinet type, hinge angle, overlay, material, and adjustment features. A clear measurement checklist ensures that every hinge fits correctly and functions smoothly, reducing the risk of costly errors. With advanced testing and large-scale production, Guangdong OULA Hardware Technology Co., Ltd. provides hardware solutions that combine precision, strength, and long-lasting soft-close performance. To learn more about specifications or to request a quotation for your next project, contact us today and experience why OULA is a trusted partner worldwide.